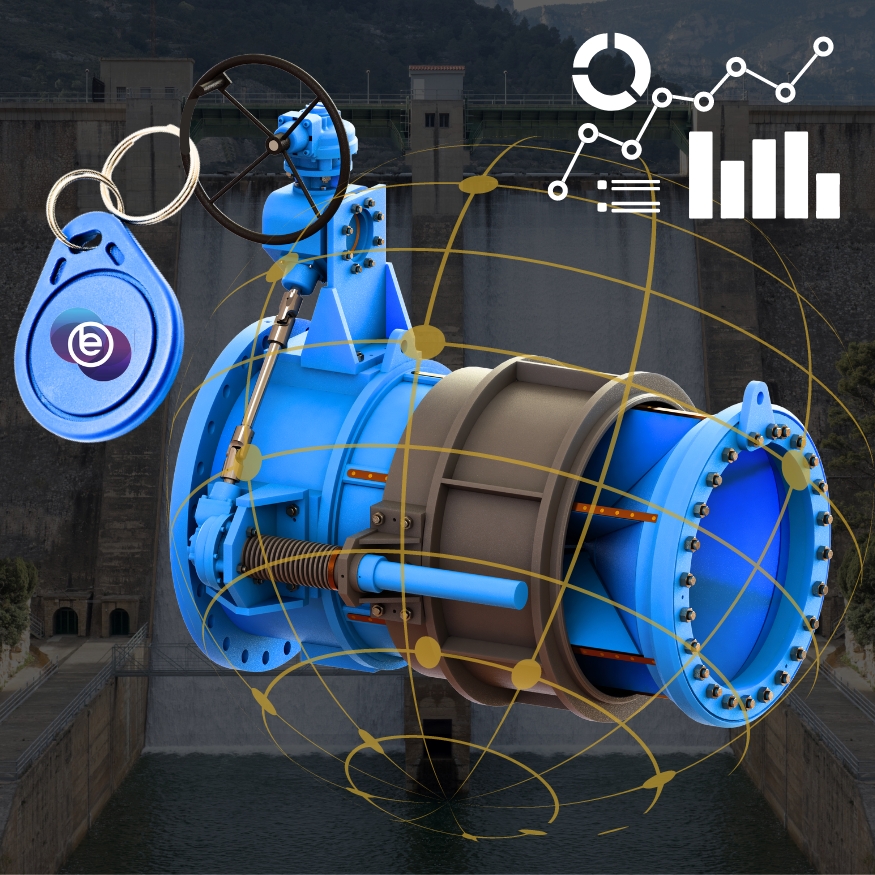

Valve Asset Management Programme

VAMP is a survaliance and maintenance programme developed by Blackhall in Brighouse that electronically captures all data pertaining to a valve either during

manufacture of a new valve / asset or retrofitted to an aged asset on site.

The system is designed to show our clients critical information via a personalised report the

age of the valve, when it was fitted, its maintenance history if any and what work would be

required to extend the assets working life.

VAMP is a survaliance and maintenance programme developed by Blackhall in Brighouse that electronically captures all data pertaining to a valve either during

manufacture of a new valve / asset or retrofitted to an aged asset on site.

The system is designed to show our clients critical information via a personalised report the

age of the valve, when it was fitted, its maintenance history if any and what work would be

required to extend the assets working life.

Also by incorporating our trademarked Valvemetrix condition based monitoring software, an asset can be monitored 24/7 remotely. Using baseline data, any changes to baseline information during operation of the valve asset will alert our monitoring team that action needs to be taken. This will help prevent further damage occurring to the valve in a bid to prevent a complete failure which can lead to costly breakdowns or worse causing harm to the environment or human life.

How it works

The VAMP engagement programme begins with the client agreeing upon the scope of the implementation. This comes about after we have spoken with the client to ascertain as much information as possible, singling out critical areas of vulnerability whilst inputting historic pieces of data as we move forward to a full physical survey.

The Valve will receive a unique VIN plate along with a report containing core data and a 'valve signature'. It is then colour tagged to highlight what type of remedial action is required. At this stage a realistic time scale for further surveying is agreed upon.

If a valve is red tagged then it is perceived to be at high risk of failure, requiring immediate

reactive intervention. The necessary work is then carried out culminating in re-tagging and

the generation of a record of the occurrence in the form of a comprehensive account. A

yellow tag suggests planned maintenance is required such as fixing a leaking gland. Any

changes can be monitored with any delta differences flagged up before the next period

commences. A green tag indicates that the valve is in good condition at the point of

inspection with no intervention needed. Ongoing monitoring then ensues, which will alert us

to any issues well before they become a catastrophic melt-point. Within the process valve

data is logged, with live reports created via in-depth analytics which crucially translate into

long term cost savings and peace of mind for the client

Our recommendation

From our experience, gained over decades within the field of valve manufacture, maintenance, refurbishment and replacement we wholeheartedly believe that VAMP is a major step forward and therefore worthy of investment. It is another area where we are prepared to stake our reputation!If you would like to know more about the ins and outs of this innovative programme please get in touch for a more thorough explanation.

See some of the benefits of VAMP below:

• Periodic Service Plan

• 100% On-Site inspection of the valves complete with summary report

• Noise and Vibration Check

• Leakage Check and Assessment

• General Condition / Paint / Environment

• Changes and Deviations since last inspection

• Cycle & Torque Test

• Remedial Actions e.g. gland tightening

• Individual Valve Condition reports

• All valves Digitally tagged

• Optional: Asset / Totex Report

• Optional: Live Status reports via VAMP app enabled for authorised users (e.g. Dam Safety Engineers) including customer portal

• Optional: External Camera Inspection (Internal if required)

• Optional: Client portal •

We look forward to seeing you soon

or if you prefer to talk, call us on: +44 (0) 1484 407080