Valve Repair & Refurbishment Service

Why Risk your asset. Let the people who know, understand, and design valves, Repair and Service your valves.

Blackhall Engineering Ltd, Taylor and Shaw Valves have more than 136 years of experience (est 1876), designing and manufacturing valves for a diverse range of industries and services. During this time all 3 companies have offered spares and provided in house and onsite service and repair support for their customers, not only on their own products but other manufacturers as well. Whether it is a single valve or an entire plant, Blackhall provides a professional service, with the experience, manufacturing capabilities and skills to ensure your valves are in the most reliable hands in the business.

Our In-House Facilities

- • Experienced personnel throughout the business averaging 18 years in the valve industry and including 9 graduates.

- • A total of approx 22,000 square feet of manufacturing and refurbishment facilities.

- • 25 tonne overhead lifting capability.

- • First class test, inspection and machining facilities.

- • Hydraulic testing up to 10,000 psig.

- • Pneumatic testing up to 3,000 psig.

- • Full cryogenic clean room and degreasing plant.

- • Comprehensive blasting and cleaning equipment.

- • Design facilities including; 2D AutoCAD, 3D Solidworks, FEA (Finite Element Analysis), CFDA (Computational Fluid Dynamic Analysis) and rapid prototyping.

Our Services

- • Worldwide field inspection and service operations.

- • Expert freeing up of seized valves

- • Qualified confined space trained personnel.

- • Valve inspection and consultancy surveys with full technical report.

- • Internal endoscopic camera inspection with recorded DVD backup, capable of entering orifice sizes as small as 6mm.

- • Retro design and installation of electric, hydraulic and pneumatic actuators relating to valve operating systems.

- • Gearbox and actuator refurbishment.

- • Root cause and failure mode analysis

- • Upgrade and enhancement of valve design

- • On-Site repairs: re-packing, lubrication, sealing & re-lapping

- • Training on valve principles and operation

Repaired valves are fully hydrostatically pressure tested and receive the same 12 months guarantee as our new valves and products.

- • Worldwide field inspection and service operations.

- • Expert freeing up of seized valves

- • Qualified confined space trained personnel.

- • Valve inspection and consultancy surveys with full technical report.

- • Internal endoscopic camera inspection with recorded DVD backup, capable of entering orifice sizes as small as 6mm.

- • Retro design and installation of electric, hydraulic and pneumatic actuators relating to valve operating systems.

- • Gearbox and actuator refurbishment.

- • Root cause and failure mode analysis

- • Upgrade and enhancement of valve design

- • On-Site repairs: re-packing, lubrication, sealing & re-lapping

- • Training on valve principles and operation

Repaired valves are fully hydrostatically pressure tested and receive the same 12 months guarantee as our new valves and products.

Valves we repair

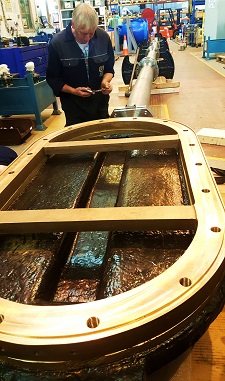

Trust Blackhall to transform any valve from scrap to

better than new condition.

On arrival at the factory, your valve is assessed before

being stripped and inspected to produce a detailed

report.

Trust Blackhall to transform any valve from scrap to

better than new condition.

On arrival at the factory, your valve is assessed before

being stripped and inspected to produce a detailed

report.

Through a combination of advanced technology,

enhanced materials and experience, Blackhall

consistently refurbish valves that are seemingly

beyond economical repair to a standard which far exceeds the original valve's performance.

All valves are 100% Factory Acceptance Tested, issued

with test certification and granted our gilt edged 20

month warranty for your ultimate peace of mind. We

are the only UK water valve manufacturer to provide

our customers with this comprehensive service.

Industries that we serve:

- Water / Dams / Reservoirs / Hydropower

- Cryogenics

- LNG / LPG

- Oil & Gas

- Pump-Protection

- Power Generation / Steam

- Boilers

- Chemical / Chlorine / Fluroine

- Pump-Protection

- Marine

Blackhall Valvologists® can repair wide range of valves such as:

- Gate Valves

- Globe Valves

- Actuated Valves

- Check Valves

- Parallel Slide Gate Valves

- Submerged Discharge Valves

- Fixed Cone Valves

- Needle / Plunger Valves

- Wedge Gate Valves

- Automatic Recirculation Valves

- Feed Check Valves

- Bellows Sealed Valves

- Vacuum Jacketed Valves

- Relief Valves

- Boiler Blowdown Valves

- Cardio Valves

- Diverter Valves

- Relief Valves

- Emergency Shut-Off Valves

- Excess Pressure Valves

- Single Spring and Double Spring Safety Valves

We look forward to seeing you soon

or if you prefer to talk, call us on: +44 (0) 1484 407080