Blackhall News

How Blackhall Engineering's Innovative Valve Maintenance Programs are Paving the Way to a Sustainable, Carbon Neutral Future

In the evolving area of climate change mediation, one critical strategy often overlooked is the preservation and maintenance of existing infrastructure. By focusing on sustaining and repairing what we already have, rather than continuously replacing and building anew, we can significantly reduce carbon footprints. This approach not only conserves resources but also minimises the environmental impact associated with manufacturing and construction. A prime example of this practice is found within the valve industry, and in particular Blackhall Engineering, who are leading the way in sustainable engineering with their VAMP and BOFIN programmes in the quest for a carbon neutral future.

In the evolving area of climate change mediation, one critical strategy often overlooked is the preservation and maintenance of existing infrastructure. By focusing on sustaining and repairing what we already have, rather than continuously replacing and building anew, we can significantly reduce carbon footprints. This approach not only conserves resources but also minimises the environmental impact associated with manufacturing and construction. A prime example of this practice is found within the valve industry, and in particular Blackhall Engineering, who are leading the way in sustainable engineering with their VAMP and BOFIN programmes in the quest for a carbon neutral future.

The Importance of Infrastructure Maintenance

Infrastructure forms the backbone of modern society, encompassing transportation networks, water supply systems, energy grids, and industrial facilities. Traditionally, the tendency has been to replace ageing infrastructure with new constructions. However, this method is resource-intensive and carbon-heavy. The production of materials such as steel and concrete for new infrastructure involves substantial carbon emissions. Additionally, the construction process itself generates further environmental impact through machinery operation, transportation of materials, and land disruption.

In contrast, maintaining and repairing existing infrastructure offers a greener alternative. It extends the life cycle of current assets, reducing the demand for new materials and the associated emissions. Moreover, it supports sustainability by promoting resource efficiency and minimising waste.

The Role of the Valve Industry

Valves play a crucial role in numerous industrial and municipal systems, including water treatment facilities, power plants, and oil and gas pipelines. These components regulate the flow of liquids and gases, ensuring the efficient and safe operation of complex systems. Given their critical function, valves are subject to wear and tear, necessitating regular maintenance and occasional repair.

The valve industry, therefore, stands at a pivotal point in the sustainability narrative. By prioritising maintenance over replacement, the industry can significantly cut down on the environmental footprint. Repairing valves instead of manufacturing new ones conserves materials and energy, contributing to lower carbon emissions.

Blackhall Engineering: A Pioneer in Sustainable Valve Solutions

Blackhall Engineering exemplifies how the valve industry can adopt sustainable practices. Specialising in the design and manufacture of high-quality valves, they are committed to the principles of durability and longevity. Their approach is centred on creating products that require less frequent replacement, thereby reducing waste and environmental impact.

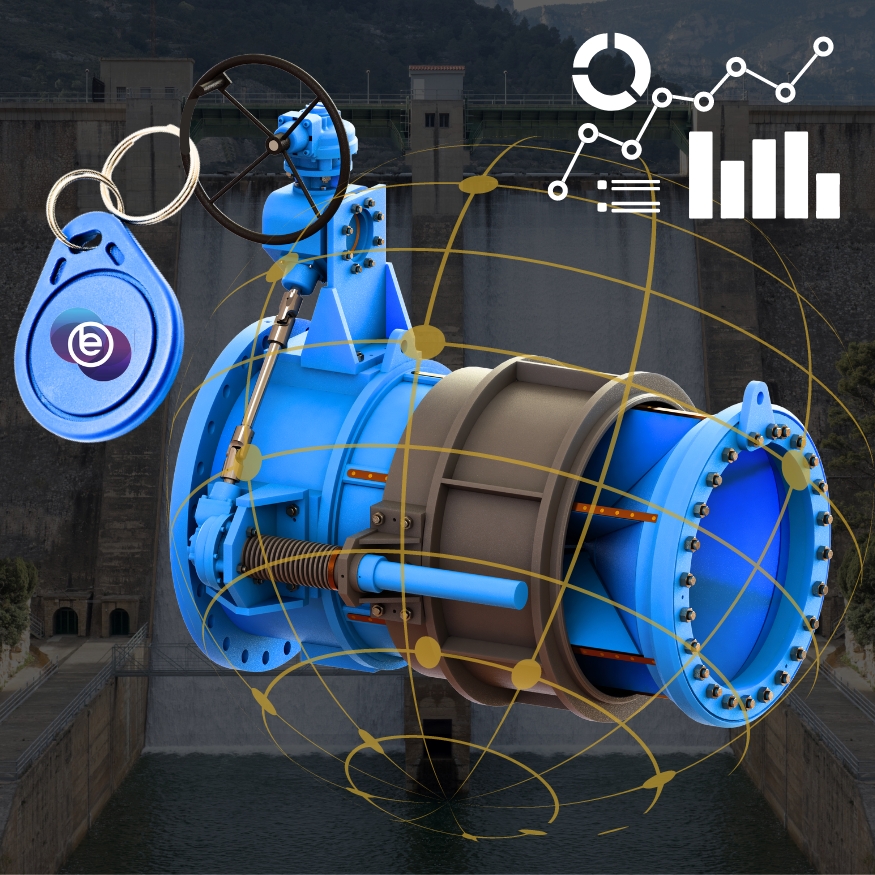

One of their key strategies is the refurbishment and upgrading of existing valve systems. This is where VAMP comes in. An innovative asset management programme it offers a sophisticated solution to the age-old challenges of valve maintenance. By electronically tagging valves, VAMP allows for comprehensive data storage and accessibility, transforming valve management into a digital, efficient process. With features such as a personalised dashboard, real-time access to valve history, maintenance records, and an early warning system, VAMP promises to mitigate costly breakdowns and extend the lifespan of critical water management assets.

Similarly, BOFIN is a nonintrusive valve service methodology that allows engineers to assess the condition of valves before operation in a safe and consistent manner. This approach complements VAMP by offering a method to evaluate valve integrity without the need for invasive procedures, thereby reducing downtime and enhancing safety.

By offering this comprehensive maintenance services, the company ensures that valves remain efficient and operational for extended periods. This not only enhances the performance and reliability of critical infrastructure but also aligns with broader environmental goals.

Conclusion

Preserving existing infrastructure through monitoring, maintenance and repair is a practical and impactful method for reducing carbon footprints. In the valve industry, this approach is particularly significant due to the crucial role valves play in various systems. Blackhall Engineering is at the forefront of this movement, demonstrating that sustainable engineering practices are not only feasible but also beneficial for the environment leading to a carbon neutral future. By prioritising durability, efficiency, and longevity, they are setting standards for how the industry can contribute to a greener future.

UK Valve Design and Manufacturer

Valves