Blackhall News

Exploring Innovation: United Utilities Considers Adopting Blackhall’s VAMP programme to help enhanced their own Asset Management Programme.

In a move to revolutionise its asset management strategies, United Utilities, a leading water utility company owning an impressive portfolio of 166 water supply reservoirs, recently visited Blackhall Engineering to explore our groundbreaking Valve Asset Management Programme (VAMP™) and the nonintrusive valve service methodology of BOFIN. This visit signifies a pivotal step towards enhancing operational efficiency, safety, and long-term cost savings through state-of-the-art valve management and maintenance technology.

In a move to revolutionise its asset management strategies, United Utilities, a leading water utility company owning an impressive portfolio of 166 water supply reservoirs, recently visited Blackhall Engineering to explore our groundbreaking Valve Asset Management Programme (VAMP™) and the nonintrusive valve service methodology of BOFIN. This visit signifies a pivotal step towards enhancing operational efficiency, safety, and long-term cost savings through state-of-the-art valve management and maintenance technology.

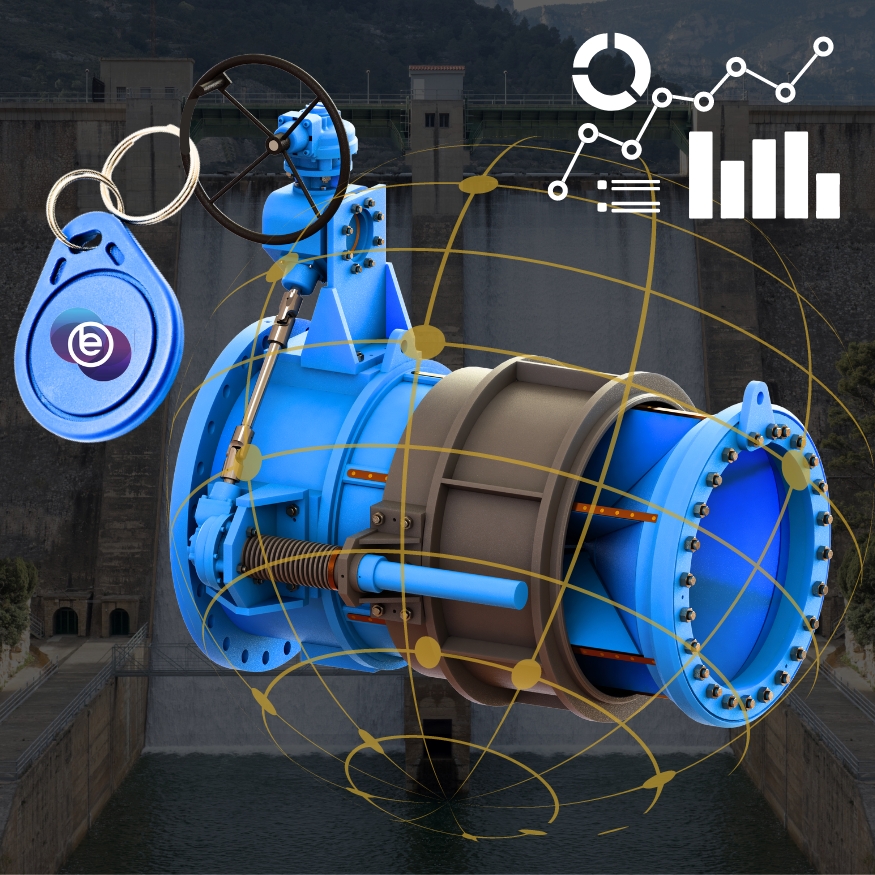

How VAMP™ Works

VAMP™, an innovative asset management programme developed by Blackhall Engineering, offers a sophisticated solution to the age-old challenges of valve maintenance. Following a comprehensive survey Blackhall’s team of highly skilled engineers will electronically tag each of the client’s valves in accordance with our colour coded advisory system Red, Amber and Green. Condition reports are then created with advisories of next steps and actions to help keep these assets in good working order. VAMP™ allows for comprehensive data storage and accessibility, transforming valve management into a digital, efficient process. With features such as a personalised dashboard, real-time access to valve history, maintenance records, and an early warning system, VAMP™ promises to mitigate costly breakdowns and extend the lifespan of critical water management assets.

The significance of VAMP™ for a water utility as vast as United Utilities cannot be overstated. With a vast array of reservoirs and the inherent complexity of water supply systems, the ability to proactively manage valve assets is crucial. VAMP™’s digital tagging and monitoring system would enable United Utilities to not only ensure the reliability and safety of its water supply but also to adhere to the latest governmental standards for reservoir safety and environmental protection.

What is BOFIN?

Similarly, BOFIN, a nonintrusive valve service methodology was introduced to United Utilities engineers. This innovative approach complements VAMP™ by offering a method to help Operatives and other skilled personal to evaluate valve health without the need for invasive procedures, thereby reducing downtime and enhancing safety.

A BOFIN course and other educational programmes will soon be available to all our customers by visiting our newly formed training academy which we plan to open our doors later this year.

The Benefits

The combination of VAMP™ and BOFIN represents a leap forward in asset management for the water industry and was highly lauded by United Utilities during their visit. For them, considering the implementation of these technologies means a transition from reactive maintenance strategies to a proactive, data-driven approach. The implications are far-reaching, from improved operational efficiency and reduced maintenance costs to enhanced regulatory compliance and environmental stewardship.

A New Era

As United Utilities is considering the potential of adopting VAMP™ and BOFIN, Blackhall Engineering’s commitment to through-life engineering services and its continuous innovation in valve technology places it at the forefront of the industry. As water utilities worldwide strive to modernise their operations and infrastructure, the relevance and appeal of VAMP™ and BOFIN are promising. United Utilities’ initiative not only highlights the company’s dedication to operational excellence and sustainability but also paves the way for a new era of asset management in the water industry.

Safeguarding the Future

In conclusion, United Utilities' visit to Blackhall Engineering to explore and potentially implement VAMP™ and BOFIN stands as a testament to the utility's forward-thinking approach to asset management. This promises to revolutionise United Utilities’ operational capabilities but also sets a benchmark for the industry, demonstrating the tangible benefits of embracing innovative technologies to safeguard critical water resources.

UK Valve Design and Manufacturer

Valves