Blackhall News

Revitalizing Kielder Reservoir: Blackhall Engineering's Expertise in Fixed Cone Valve Repair

Kielder Reservoir was opened in 1982 by the then queen, Elizabeth II. It cost £167 million to

build and is capable of holding 200,000 million litres (44 million gallons) of water, making it

northern Europe’s largest man-made lake, as well as being surrounded by England’s largest

forest. During its implementation on-site employment reached peaks of 1,500 engineers and

construction workers.

Kielder Reservoir was opened in 1982 by the then queen, Elizabeth II. It cost £167 million to

build and is capable of holding 200,000 million litres (44 million gallons) of water, making it

northern Europe’s largest man-made lake, as well as being surrounded by England’s largest

forest. During its implementation on-site employment reached peaks of 1,500 engineers and

construction workers.

Water release, which is capable of peaking at a maximum of 1,300 million litres per day, is controlled from the valve tower, which stands 70m (230 feet) high and is accessed via a tunnel that runs underneath the reservoir.

The outlet valve

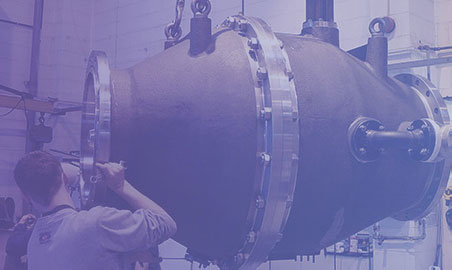

Commissioned in 1977, the valve installed on the outlet pipe, which allows water to escape into what we call a spillway when the reservoir levels need to be dropped in an emergency, had been working for nearly forty years when it found itself being labelled as irreparable, after decades of valiant service. However, when Blackhall Engineering were approached to look into the problem their team of engineers realised that it could be repaired and retro-fitted. The valve was removed from the outlet pipe, ready for a full assessment and inspection before being meticulously honed to allow it to function at peak performance once again.

With decades of experience in valve repair and refurbishment services, we also recognised an opportunity to showcase our modern mastery and broadcast our newly formed Through-Life Engineering Services (TES) division. We took this vintage Fixed Cone Valve into our care, not just to refurbish it but to transform it entirely

More about TES

Essentially TES can be viewed as a defined process that allows a company like Blackhall to provide support throughout each stage of a product’s lifecycle – from conception, through design, manufacture and operational cycle, to end-of-life disposal. It is seen as a natural stage in the evolution of product support and maintenance, repair and overhaul strategy with huge cost savings across the board.

TES forms the basis for everything that Blackhall does. From the outset we have felt it incumbent to supply high-quality, long lasting critical assets to the water and power industry and also to be able to offer a comprehensive after installation service too. It is something that is now being formalised, with its constituent parts joined up to become a recognised service.

As TES is a relatively new concept everyone is coming to the show rather late. We’re picking up the challenge from engineering projects that were signed off at the turn of the last century or forty years ago. Besides implementing TES on new installations Blackhall are committed to restoring assets that are 100 plus years old, rather than simply scrapping and replacing components. It makes sense in so many ways.

Back to Kielder

The Kielder valve was given a full assessment before being meticulously stripped and inspected. A detailed report was compiled, laying the groundwork for a restoration that would integrate advanced technology and superior materials coupled with our unrivalled expertise.As the only UK water valve manufacturer offering this level of comprehensive service, we are proud to be the standard-bearers of innovation and reliability.

So, don’t let the past be the end of your valve's story. Your dams and reservoir valves have a history worth preserving and a future worth continuing. At Blackhall we can make this happen.

UK Valve Design and Manufacturer

Valves