Blackhall News

Introducing VAMP: a giant leap for the power of Valvology®

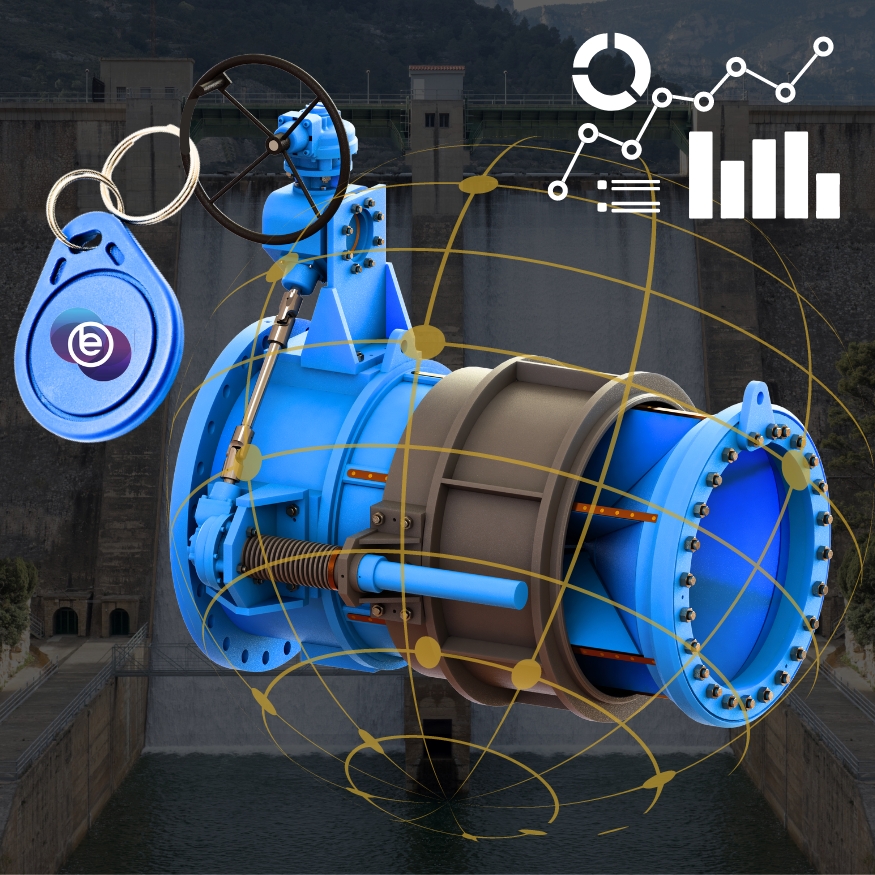

So, what is VAMP?

VAMP is an asset management programme we have developed that electronically

tags a valve, allowing all data about the valve to be electronically stored and

accessed from anywhere. Similar to a smart meter but tailored to valves, VAMP is an

asset management programme developed to electronically tag valves. With just a

click, you’ll see a personalised dashboard in which you can instantly see the valve's

age, installation date, maintenance records and necessary parts for ongoing upkeep.

It also features an early warning message system to help mitigate costly

breakdowns.

VAMP is an asset management programme we have developed that electronically

tags a valve, allowing all data about the valve to be electronically stored and

accessed from anywhere. Similar to a smart meter but tailored to valves, VAMP is an

asset management programme developed to electronically tag valves. With just a

click, you’ll see a personalised dashboard in which you can instantly see the valve's

age, installation date, maintenance records and necessary parts for ongoing upkeep.

It also features an early warning message system to help mitigate costly

breakdowns.

Developed and trademarked by Blackhall Engineering, VAMP tags are now fitted to all valves that leave our factory, meaning that if it’s a service our clients deem worthy of the investment – which, from experience, we believe it is – each client’s new valve will leave our factory VAMP enabled.

Is VAMP really necessary?

As with any new technology there is often the question of whether it’s really necessary. But then, is necessity not the mother of all invention? With valves especially, there is a responsibility for those accountable for their correct performance and maintenance to ensure that they never fall below the minimum standards expected of them. This is especially true where valves are used to move chemicals or other toxic substances, or where lack of correct maintenance poses a threat to public wellbeing. Making sure you get ahead of any issues that could arise is all part of your corporate responsibility, and a good example would be our water supply. In fact, in July this year, the Government published its commitment to improving reservoir safety with reforms to the regulatory regime, and modernisation of the Reservoirs Act 1975.

This will include the introduction of reviews of engineers’ reports by the Environment Agency and the regulation of reservoirs using a modern, risk-based approach. This needn’t be a worry; depending on the information you require in order to meet the Government’s changing expectations, we can personalise your dashboard to ensure your reports meet the standard and that any risks posed to the public by improperly maintained valves are mitigated where possible.

Extending the life of your assets

VAMP is a tool that promises to protect your investment, whether you’re investing in new valves, or have valves already in place. VAMP can be retrofitted to existing equipment and although I’ve said it before, I’ll say it again: Blackhall Valves are manufactured to a high standard, and whilst more expensive when compared to mass-made alternatives that you might import from other countries, they are made to last. Investment in VAMP – be that for a new or existing valve – ensures that our products will last even longer.

Saving you time and money

As the Government looks to implement the new reforms, VAMP will also save you time by allowing you time to plan for maintenance rather than having issues suddenly forced upon you. This is more efficient for the engineers, too; allowing Blackhall to diagnose the problem for the Engineer means they needn’t spend undue hours on your site trying to first figure out the issue. After all, time is money!

How it works

The VAMP engagement programme begins with your agreement on the scope of the implementation. This comes about after we have spoken with you to ascertain as much information as possible, singling out critical areas of vulnerability whilst inputting historic pieces of data as we move forward to a full physical survey. The assessment is rounded out with photographs of the valve.

Once this is done the valve will receive a unique VIN plate along with a report containing core data and a 'valve signature'. It is then colour tagged to highlight what type of remedial action is required. At this stage a realistic time scale for further surveying is agreed upon.

If a valve is red tagged then it is perceived to be at high risk of failure, requiring immediate reactive intervention. The necessary work is then carried out culminating in re-tagging and the generation of a record of the occurrence in the form of a comprehensive account. A yellow tag suggests planned maintenance is required such as fixing a leaking gland. Any changes can be monitored with any delta differences flagged up before the next period commences. A green tag indicates that the valve is in good condition at the point of inspection with no intervention needed. Ongoing monitoring then ensues, which will alert us to any issues well before they become a catastrophic melt-point. Within the process valve data is logged, with live reports created via in-depth analytics which crucially translate into long term cost savings and peace of mind for the clien

All part of the service

End-to-end care is a critical part of the Blackhall service. Ours is, after all, a specialised product and so one of our main aims is to provide a service that not only makes and supplies the valves, but that then maintains them for life – we call this Through Life Engineering (TES).. This hasn’t changed, and I’m putting my stake in the ground and saying that it never will. What it will do is evolve, as our development of VAMP proves.

This innovative new programme is not a replacement for the lifetime care on which we have built our reputation, but a worthy addition to it. Investment in VAMP enables your business to be pro-active rather than reactive, and with a dashboard personalised to you, plus a team of Blackhall engineers able to act on the information it provides in as time-efficient a way as possible, whilst the initial investment is substantial, I can promise you this: in the long term, VAMP will save you time and money

UK Valve Design and Manufacturer

Valves