1. Can you explain how the Renov8 initiative aligns with Blackhall’s broader sustainability goals, particularly in reducing carbon emissions through valve refurbishment?

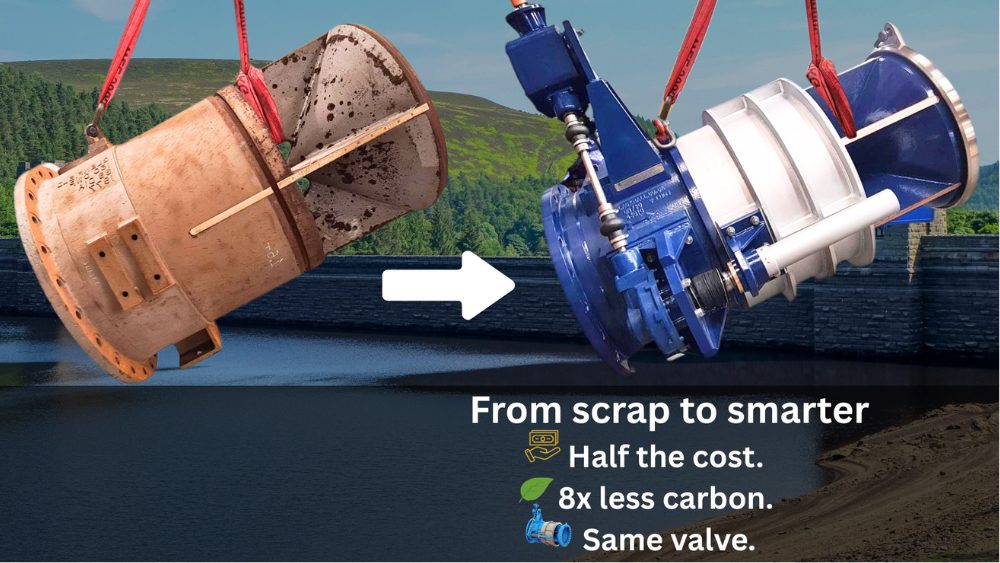

Blackhall, like many businesses, is working towards net-zero emissions to help achieve our sustainability goals, as are the water companies. As an SME, there are limited changes we can implement to make a difference, such as changing lightbulbs to LED and examining our extraction systems in the warehouse. However, it is the larger organisations that will make the biggest impact. So, we asked ourselves how we could help the water companies achieve their goals. They will not meet their targets by removing old assets from sites across the country only to replace them with cheaper imported products, which negatively impacts the environment through shipping from Asia and other countries. Therefore, why not look closer to home? Working with Northumbrian Water, we took on the challenge to compare the carbon impact of importing new products versus refurbishing the same size valve in the UK. We enlisted the help of a student from Edinburgh University to act as our carbon champion, tasked with exploring government policy and comparing the carbon impact of like-for-like options. The results are impressive. Through RenoV8, we helped reduce carbon output by eight times. (Copies of the report are available for a fee.)

2. What specific valve types are best suited for refurbishment under the Renov8 programme, and how does this impact their lifespan compared to new valves?

Blackhall can RenoV8 any type of valve asset, regardless of age, as long as the asset meets certain criteria, especially when we use our technology to investigate the strength of the main pressure envelope (valve body).

It is worth noting that there are competitors in the market who can offer a similar service, but they can’t repair every type of valve. At Blackhall, we can. We are the only company that owns the IP to the Larner Johnson range of valves and official spares. In fact, valves that have been refurbished at Blackhall are expected to go on for a further 50-plus years with regular maintenance.

3. Could you provide insights into the cost savings achieved through the Renov8 initiative, regarding reduced manufacturing needs and long-term operational efficiency?

The Kielder valve project is a good example. When compared to the cost of a new fixed cone valve, Blackhall was able to refurbish the DN750 FCV for 60% of the cost of a replacement one. We also provided an extended warranty and are confident that this valve will be in service for another 50 years.

4. How does valve refurbishment help your clients contribute to their carbon neutrality targets, particularly in the water management and energy industries?

With shorter lead times to refurbish an asset, as opposed to replacing it, clients benefit from overall cost savings and the knowledge that their carbon footprint is being reduced eight times over. So, they’re not just receiving value for money that is reducing their carbon footprint but a product that will go on to operate for another 50 years with the right care.

5. How does Renov8 integrate with Blackhall’s other maintenance and asset management services like VAMP® and BOFIN to enhance valve longevity and reliability?

Before VAMP®, Blackhall relied on the water industry to contact Blackhall with its valve problems. Since the introduction of VAMP®, we have used this service to help us secure an agreement with the water company giving us access to their Dam or Reservoir. By carrying out valve health checks, we are best placed to find assets that need repair or refurbishment. RenoV8 has become an integral part of the service offering to our customers.