Blackhall News

Blackhall Engineering's Shaw valves elevate safety & efficiency for the world’s leading integrated manufacturer of titanium dioxide pigment.

How we got to here

“You need to know a lot about your own tiny field of expertise, but for the vast majority of life’s

necessities you rely blindly on the help of other experts, whose own knowledge is also limited to

a tiny field of expertise.”

“You need to know a lot about your own tiny field of expertise, but for the vast majority of life’s

necessities you rely blindly on the help of other experts, whose own knowledge is also limited to

a tiny field of expertise.”

When contemplating our modern existence, the statement above holds true. The more we move forward the more specialised our individual knowledge becomes. The more dependent we become on others to remain sheltered, clothed, fed and entertained. Can the contemporary artist mix their own paints, can we build our own mode of transport from scratch? In a sense it is the amplification of where we’ve been heading as a species since the first agricultural revolution. For a broader view upon this subject, I’d recommend, unless you already have, reading the book from which the quote comes – Sapiens: A Brief History of Humankind by Yuval Noah Harari.

Speciality – a case in point

Continuous advancements in valve technology, including innovations in design, materials, and manufacturing processes, have contributed to the market growth. These innovations have resulted in valves that can withstand higher pressures, handle more challenging operating conditions providing enhanced efficiency and durability. With the evolving needs of modern industrial processes, the availability of cutting-edge valve solutions has generated a need for more and more specialist solutions.

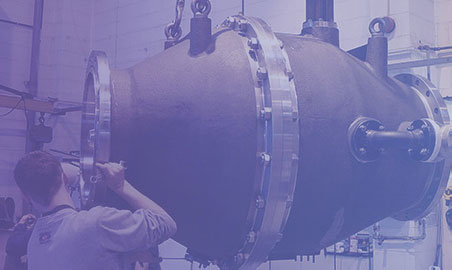

Instrumental in the provision of these solutions is Blackhall Engineering, an eminent name in the valve manufacturing industry, renowned for its cutting-edge products and commitment to quality. Our Shaw range of zero-emission valves, acquired in 2007, have been internationally recognised for their innovative design and environmental efficiency. In fact, these valves have even achieved the prestigious Queen’s Award for Environmental Efficiency. Our team of Valvologists utilise leading technologies to create valves that surpass industry expectations. We're more than just a valve manufacturer, we're a provider of safety and peace of mind for our customers and the environment.

Specialism and our expertise

Among our range of reliable and safe valves, the Accessible Bellows Sealed Globe Valves (named after the shape of its body) stand out. They are extremely efficient and are specifically designed for the safe handling of hazardous chemicals. Built for durability, with a minimum three-ply construction that ensures zero emissions, they are also equipped with secondary low emission PTFE packing that eliminates leakage. They form part of our range of specialist valves that play a crucial role in different industrial applications, ensuring the smooth operation and efficiency of various systems. You’ll find our industrial valves in a wide range of sectors, including the oil and gas industries, the chemical sphere, power plants, water supply systems, wastewater treatment and many others. They are expertly designed to handle different types of fluids and provide accurate control over their flow, contributing to the overall functionality and safety of industrial operations.

A success story for a titanium dioxide producer

Blackhall Engineering has helped a globally recognised American titanium dioxide producer with around 6,600 employees spread across all six continents. The company mines and processes titanium ore, zircon, and other materials and manufactures titanium dioxide pigment, specialty titanium dioxide products and high-purity titanium chemicals. Their products lend brightness and durability to paints, coatings, inks, plastics, paper, and a myriad of everyday items. Their commitment to sustainability is reflected in their strategy to integrate it into every aspect of their business, making them the world's leading vertically integrated titanium dioxide producer. The integration of Blackhall's Accessible Bellows Sealed Globe Valves has revolutionised their operations since 2017, particularly in their Middle Eastern facilities. The zero-leakage feature of these valves has proven paramount in ensuring safety during the handling of hazardous chemicals.

Yet again, these valves have demonstrated superior reliability and efficiency, significantly reducing the risk of accidents and boosting operational performance. Their zero-emission feature aligns perfectly with the company’s commitment to sustainability, making them an ideal solution.

Specialism and co-operation

The collaboration between the two companies highlights how innovative solutions can transform industrial processes. Our commitment to quality and safety, combined with determination for sustainable practices, paves the way to a brighter, safer future. In conclusion, the story of Blackhall Engineering's Shaw Bellows Sealed Globe Valves and their placement, is a testament to the power of innovation and commitment to quality. It's a story of how world-class engineering solutions can foster safety, efficiency, and sustainability in some of the most challenging industrial environments. It is also a prime example of how in order to progress we need people and companies who are specialists within a given field and who can feed into the wider milieu through partnership.

UK Valve Design and Manufacturer

Valves