Blackhall News

Advancing Marine Sustainability: The Critical Role of Blackhall's Cryogenic LNG Valves in LNG Transportation

In the highly competitive and rapidly evolving LNG vessel sector, Blackhall Cryogenic LNG valves are distinguished by their advanced design and reliability. These valves are essential for maintaining the structural integrity and operational efficiency of LNG tanks. They help control the pressure and temperature within the tanks, where LNG is stored at -162 degrees Celsius, and manage 'boil-off' gas that occurs when LNG evaporates due to heat.

The importance of robust, high-quality, long-lasting valves in the LNG transportation system cannot be overstated. Given the critical nature of transporting LNG, which is a cleaner alternative to traditional fossil fuels, the valves must perform flawlessly under extreme conditions to prevent any potential leaks or failures. These failures could not only lead to economic losses but also pose serious environmental and safety risks.

For over half a century, Blackhall Engineering has been at the forefront of cryogenic valve manufacturing, establishing close ties with leading industrial gas companies worldwide. Accepted in over 80 countries, Blackhall valves are synonymous with quality and reliability. This reputation reflects the company's commitment to meeting the stringent requirements of the global shipping industry, which increasingly prioritises environmental sustainability and safety.

Blackhall's range of Cryogenic LNG valves is particularly notable for setting the standard in LNG valve technology. Every valve undergoes rigorous temperature, pressure, and helium tests at advanced testing facilities, ensuring each component can withstand the most demanding conditions.This rigorous testing protocol highlights Blackhall’s commitment to excellence and safety. Additionally, each valve achieves certification from globally recognised classification societies such as ABS, DNV, Lloyds, BV and Korean Register certification, further attesting to its quality and making it a key player in the transition toward cleaner fuel alternatives in marine operations.

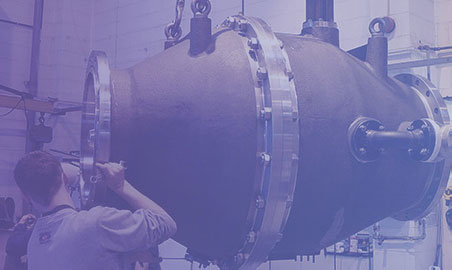

Moreover, Blackhall Engineering’s dedication extends beyond manufacturing. The company's Cryogenic Valve Clinic offers comprehensive services that include maintenance, repair, and refurbishment. This holistic approach ensures the longevity and reliability of their products, emphasising Blackhall's commitment to superior valve solutions.

As the marine industry continues its shift towards cleaner, more sustainable fuel options like LNG, the significance of Blackhall’s Cryogenic LNG valves grows. They not only represent a technological achievement but also embody Blackhall's commitment to environmental stewardship. Their ongoing advancements in LNG valve technology are crucial for shaping a more sustainable and efficient marine industry, proving that innovation and environmental responsibility can indeed go hand in hand.

UK Valve Design and Manufacturer

Valves