In the rapidly evolving energy landscape, hydrogen is swiftly emerging as a vital force in the transition to a sustainable, low-carbon future. As nations worldwide work to reduce their dependence on fossil fuels and meet ambitious net-zero targets, the demand for hydrogen - clean, versatile, and abundant - continues to soar.

With over a half a century of expertise, Blackhall Engineering has been at the forefront of this transformation, designing and manufacturing advanced hydrogen valves since 1966. With a strong focus on innovation, precision, and sustainability,

Blackhall has become a global leader in the field, offering reliable valve solutions that meet the industry's highest standards. Our hydrogen valves are not only a testament to our engineering excellence but also to our commitment to shaping a greener future. As the world embraces hydrogen, Blackhall's expanding international presence and unwavering dedication to quality position us as a trusted partner, driving progress in the global energy transition.

Our Hydrogen Valves

Vacuum Jacketed Globe Stop Valve

- Series: 2027 & 9027

- Type: Non Bellows

- Rating: CL150 to CL600; PN16 to PN100

- Material: Stainless Steel 316

- Size Range: ½” – 8”; DN15 – DN200

- End Connections: Butt Weld, Socket Weld, Screwed, Flanged

- Temperature Range: -269 °C to +149°C

Vacuum Jacketed Globe Control Valve

- Series: 9029

- Type: Bellows Sealed

- Rating: CL150 to CL600; PN16 to PN100

- Material: Stainless Steel 316

- Size Range: ½” – 8”; DN15 – DN200

- End Connections: Butt Weld, Socket Weld, Screwed, Flanged

- Temperature Range: -269 °C to +149°C

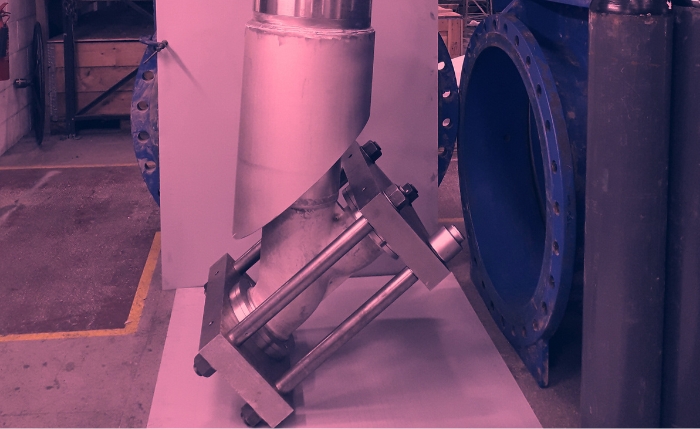

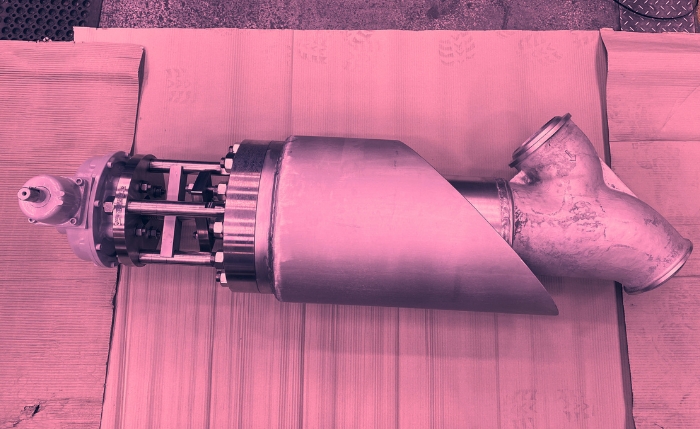

Y-Pattern Stop Valve

- Series: 9031

- Type: Bellows Sealed

- Rating: CL150 to CL600; PN16 to PN100

- Material: Stainless Steel 316

- Size Range: ½” – 8”; DN15 – DN200

- End Connections: Butt Weld, Socket Weld, Screwed, Flanged

- Temperature Range: -269 °C to +149°C

Y-Pattern Control Valve

- Series: 9032

- Type: Bellows Sealed

- Rating: CL150 to CL600; PN16 to PN100

- Material: Stainless Steel 316

- Size Range: ½” – 8”; DN15 – DN200

- End Connections: Butt Weld, Socket Weld, Screwed, Flanged

- Temperature Range: -269 °C to +149°C

Check Valves

- Series: 9501

- Type: Piston Type

- Rating: CL150 to CL600; PN16 to PN100

- Material: Stainless Steel 316

- Size Range: ½” – 8”; DN15 – DN200

- End Connections: Butt Weld, Socket Weld, Screwed, Flanged

- Temperature Range: -269 °C to +149°C

Diverter Valves

- Series: 2005

- Type: 3-Way Divertor

- Rating: CL150 to CL300; PN16 to PN50

- Material: Stainless Steel 316 / Bronze

- Size Range: ½” – 8”; DN15 – DN200

- End Connections: Butt Weld, Socket Weld, Screwed, Flanged

- Temperature Range: -269 °C to +149°C

Download Our Hydrogen Valves Brochure

To learn more about Blackhall's innovative hydrogen valve solutions, download our brochure and discover how over half a century of engineering excellence has positioned us as leaders in the global energy transition.

If you have any questions or would like to explore how our valves can support your project, don't hesitate to get in touch with our expert team. We are here to help drive your success.

Also Read

We look forward to seeing you soon

or if you prefer to talk, call us on: +44 (0) 1484 407080