Cryogenic Globe, Gate, Diverter & Special Valves

Globe Valves

(Non-Ext & Extended)

(Regulating, Check & Stop Check)

Series 2000:

Tanker Range

Series 9000:

ASU Range

Size:

1/2" - 8";

DN15 - DN200

Material:

Pressure Rating:

End Connections

Temperature:

Bronze,

Stainless Steel

Monel &

Class150 to 1500;

PN16 to PN100

Butt Weld, Flanged,

Socket Weld &

Screwed

-196'C to +65'C

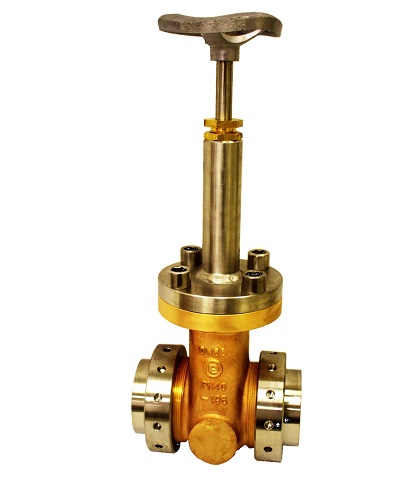

Cryogenic Gate Valves

Series 2000:

Tanker Range

Series 9000:

ASU Range

Size:

1/2" - 8";

DN15 - DN200

Material:

Pressure Rating:

End Connections

Temperature:

Bronze,

Stainless Steel

Monel &

Class150 to 1500;

PN16 to PN100

Butt Weld, Flanged,

Socket Weld &

Screwed

-196'C to +65'C

Vacuum Jacketed Valves

Series 2027:

Non Bellows Sealed

Series 2028:

Bellows Sealed

Size:

1/2" - 8";

DN15 - DN200

Material:

Bronze,

Stainless Steel &

Aluminium

Pressure Rating:

Class150 to 600;

PN16 to PN40

End Connections

Butt Weld, Flanged,

Socket Weld &

Screwed

Temperature:

-269'C to +149'C

Emergency Shut-Off/

Excess Pressure Valves

Series 2020:

Gate

Series 2003:

EPD

Size:

1/2" - 3";

DN15 - DN80

Material:

Bronze,

Stainless Steel

Pressure Rating:

Class150 to 600;

PN16 to PN40/50

End Connections

Butt Weld,

Flanged,

Socket Weld &

Screwed

Temperature:

-196'C - +65'C

3-Way Diverter &

4-Way Cardio Valves

Series 2005:

3-way Divertor

Series 1005/6:

4-Way Cardio

Size:

1" - 8";

DN25 - DN200

Material:

Bronze,

Stainless Steel,

Monel &

Aluminium

Pressure Rating:

Class150 to 600;

PN16 to PN40/50

End Connections

Screwed, Flanged

Temperature:

-196'C - +65'C

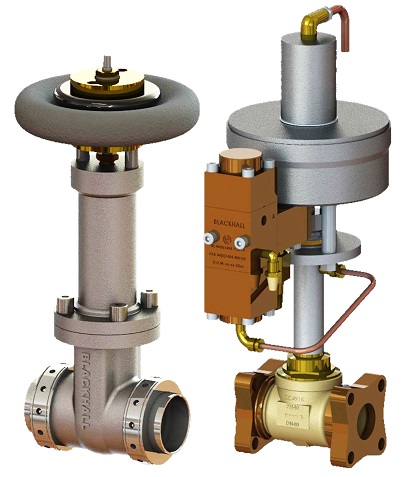

Other Special Valves

Series 2012/2013:

In-Line Relief Valve

Series 2014/2015:

Y Strainer

Series 2002:

Cluster Valve

Series 9300/2011:

Globe Actuated Valve

Series 2201:

Globe Angle Valve

Series 2001:

Vacuum Probe Valve

Series 2008:

In-Line Relief Valve

Series 2006:

Vacuum Probe Valve

Series 2019:

Thermo Check

Hot Ideas for Cool Solutions

Blackhall Engineering has been manufacturing a wide range of cryogenic valves for over 50 years, and by working closely with the world's leading industrial gas companies our valves are now accepted globally in over 80 countries. Air separation plants utilise a low-temperature rectification process to produce oxygen, nitrogen, argon, helium etc. Blackhall have created an industry leading product range that is ideally suited for all cryogenic applications.

Our valves are used widely in the production, storage and transportation of all cryogenic fluids and are designed to meet international Industrial Gas specifications, with stringent testing taking place to the applicable standards in our clean room & testing facility. In addition to supplying new valves the Blackhall Cryogenic Valve Clinic offers a full service, repair and refurbishment programme.

Our valvologists continue to embrace leading technologies and as a result the Blackhall team use the latest CFDA, FEA and seismic analysis ensuring that our customers receive high performance valves.

All this combined with Blackhall's desire to exceed customer expectations help to create the ultimate valve experience.

Contact us

Have an Enquiry? Get in touch.

![]() enquiry@blackhall.co.uk

enquiry@blackhall.co.uk

![]() +44 (0) 1484 407080

+44 (0) 1484 407080